Method steps

1. The sprocket should be installed on the shaft without skew or swing. In the same transmission assembly, the end faces of the two sprockets should be in the same plane. When the center distance of the sprocket is below 0, 5 meters, the allowable deviation is 1 mm; when the center distance of the sprocket is above 0, 5 meters, the allowable deviation is 2 Mm. However, it is not allowed to rub the side of the sprocket teeth. If the two wheels offset too much, it will easily cause chain disconnection and accelerated wear. When replacing the sprocket, you must pay attention to check and adjust the offset.

2. The tightness of the chain should be appropriate. Too tight increases power consumption and bearings are easy to wear; too loose chain is easy to jump and fall off. The tightness of the chain is: lifted or pressed down from the middle of the chain, the center distance between the two sprockets is about 2-3cm.

3. The new chain is too long or stretched after use, which is difficult to adjust. You can remove the chain link depending on the situation, but it must be an even number. The chain link should pass through the back of the chain, the lock piece should be inserted outside, and the opening of the lock piece should face the opposite direction of rotation.

4. After the sprocket is severely worn, the new sprocket and the new chain should be replaced at the same time to ensure good meshing. It is not possible to just replace a new chain or a new sprocket alone. Otherwise it will cause poor meshing and accelerate the wear of the new chain or new sprocket. When the tooth surface of the sprocket is worn to a certain degree, it should be turned over and used in time (referring to the sprocket used with adjustable surface). To extend the use time.

5. The old chain cannot be mixed with part of the new chain, otherwise it is easy to have an impact in the transmission and break the chain.

6. The chain should be filled with lubricating oil in time during work. The lubricating oil must enter the matching gap between the roller and the inner sleeve to improve working conditions and reduce wear.

7. When the machine is stored for a long time, the chain should be removed and cleaned with kerosene or diesel oil, and then coated with oil or butter and stored in a dry place to prevent corrosion.

Visual inspection of the chain

1. Whether the inner/outer chain piece is deformed, cracked or embroidered

2. Whether the pin is deformed or rotated, embroidered

3. Whether the roller is cracked, damaged or excessively worn

4. Whether the joint is loose and deformed

5. Whether there is abnormal noise or abnormal vibration during operation, and whether the chain lubrication is in good condition

Testing method

The chain length accuracy should be measured according to the following requirements:

1. The chain is cleaned before measurement

2. Wrap the chain to be tested on two sprockets, and the upper and lower sides of the chain to be tested should be supported

3. The chain before the measurement should stay for 1 min under the state of applying one-third of the minimum ultimate tensile load

4. When measuring, apply the specified measuring load on the chain to make the upper and lower chains tensioned, and the chain and the sprocket should ensure normal meshing

5. Measure the center distance between two sprockets

Measuring chain elongation

1. In order to remove the clearance of the entire chain, it is necessary to measure under a certain degree of pulling tension on the chain.

2. When measuring, in order to minimize the error, measure at 6-10 knots

3. Measure the inner L1 and outer L2 dimensions between the rollers of the number of pitches to find the judgment dimension L=(L1+L2)/2

4. Calculate the elongation length of the chain. This value is compared with the use limit value of the chain elongation in the previous item.

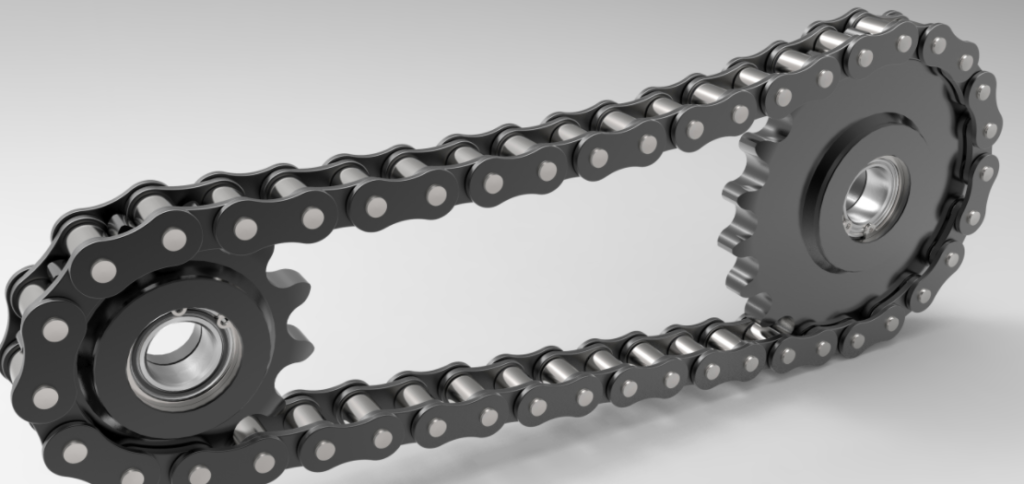

Chain structure: It is composed of inner chain links and outer chain links. It is composed of five small parts: inner chain plate, outer chain plate, pin, sleeve and roller. The quality of the chain depends on the pin and sleeve.