a professional manufacturer of chains and sprockets

Welded-Steel-Type Drag Chains

Welded-Steel-Type Drag Chains

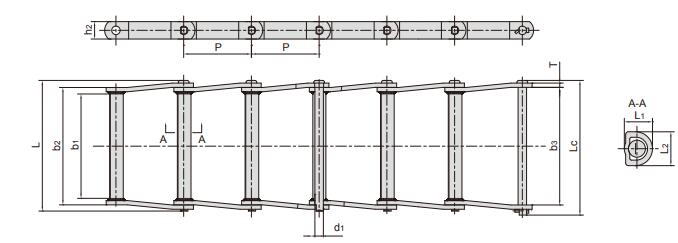

The structure of Welded-Steel-Type Drag Chains is basically the same as the engineering welding structure bending chain. The sleeve welded to the bending chain plate is a non-circular shaped tube. The outer surface of the sleeve meshes with the sprocket, and the non-circular surface is connected to the chain. The running direction is the same, and it is used to push or scrape materials.

description

Welded-Steel-Type Drag Chain is a chain used on the traction conveyor, which is suitable for conveying large or accumulated bulk materials.

parameter

| ISO Chain No. | Pitch | Bush A-A section length | Bush A-A section height | Width between narrow linkend | Pin diameter end | Width over narrow linkend | Width between broad linkend | Plate depth | Pin length | Plate thickness | ||||||||

| P | L1 | L2 | b1 min | d1 max | b2 max | b3 min | h2 max | L max | Lc max | T | ||||||||

| mm | mm | mm | mm | mm | mm | mm | mm | |||||||||||

| WD102 | 127.0 | 31.7 | 39.1 | 162.0 | 19.13 | 197.1 | 197.6 | 38.12 | 255.6 | 245.4 | 9.7 | |||||||

| WD104 | 152.4 | 31.7 | 39.1 | 104.6 | 19.13 | 136.9 | 137.4 | 38.12 | 188.0 | 181.4 | 9.7 | |||||||

| WD110 | 152.4 | 31.7 | 39.1 | 228.6 | 19.13 | 263.9 | 264.4 | 38.12 | 315.0 | 308.6 | 9.7 | |||||||

| WD112 | 203.2 | 31.7 | 39.1 | 228.6 | 19.13 | 263.9 | 264.4 | 38.12 | 315.0 | 308.6 | 9.7 | |||||||

| WD113 | 152.4 | 33.2 | 39.1 | 228.6 | 22.30 | 270.2 | 270.7 | 38.12 | 330.2 | 322.3 | 12.7 | |||||||

| WD116 | 203.2 | 36.6 | 45.2 | 330.2 | 19.13 | 359.1 | 359.6 | 45.21 | 410.4 | 405.9 | 9.7 | |||||||

| WD118 | 203.2 | 44.5 | 51.8 | 336.5 | 22.30 | 378.2 | 378.7 | 51.80 | 440.0 | 431.1 | 12.7 | |||||||

| WD122 | 203.2 | 44.5 | 51.8 | 222.2 | 22.30 | 260.6 | 261.1 | 51.80 | 324.2 | 314.5 | 12.7 | |||||||

| WD480 | 203.2 | 44.5 | 51.8 | 282.4 | 22.30 | 324.1 | 324.6 | 51.80 | 387.6 | 378.0 | 12.7 | |||||||

if you have any needs or questions about our products, contact us. Email:sales@chainsdrive.com